2010 Homag Profi KAR 310/6/A3 Edgebander

2010 Homag Profi KAR 310/6/A3 Edgebander

Description

The Homag Profi KAR 310 Edgebanders are the work-horses of the industry - reliable and efficient.

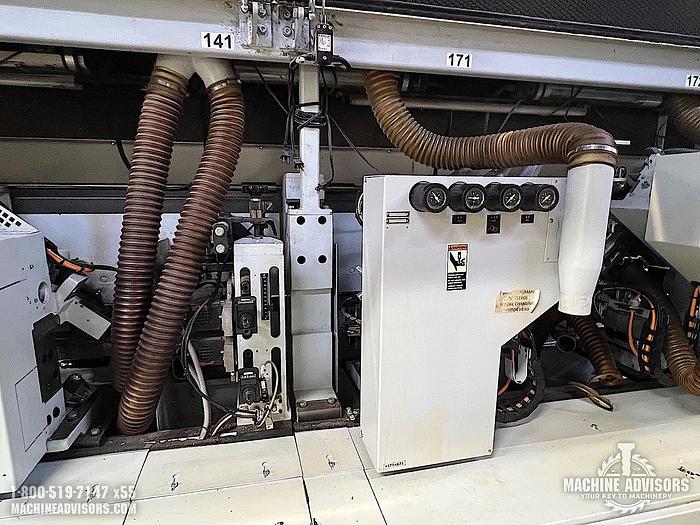

Working Capacity, 0.3 - 3 mm Edge thickness cap., min. panel width 55 mm; max. panel thickness 60 mm; feed speed variable from 18 - 25 MPM (59 - 82 FPM).

Equipped with:

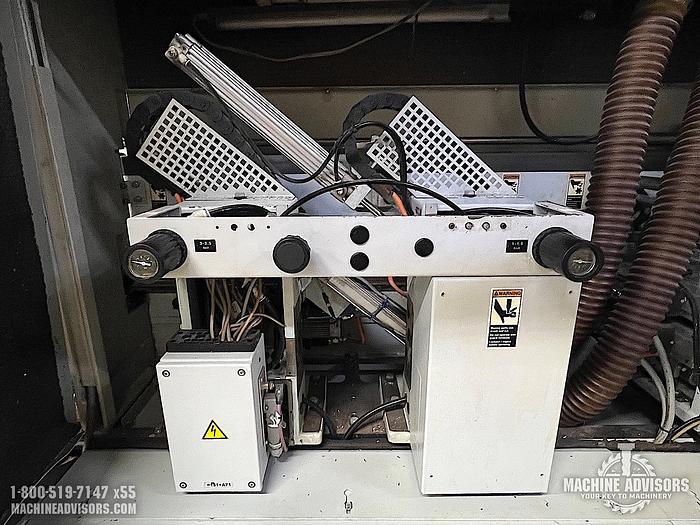

- Pre-Milling Unit: (2) Motors, 3 kW - 9,000 RPM each motor; pneumatic controlled/jump milling spindles and adjustable, manual with digital indicator infeed fence.

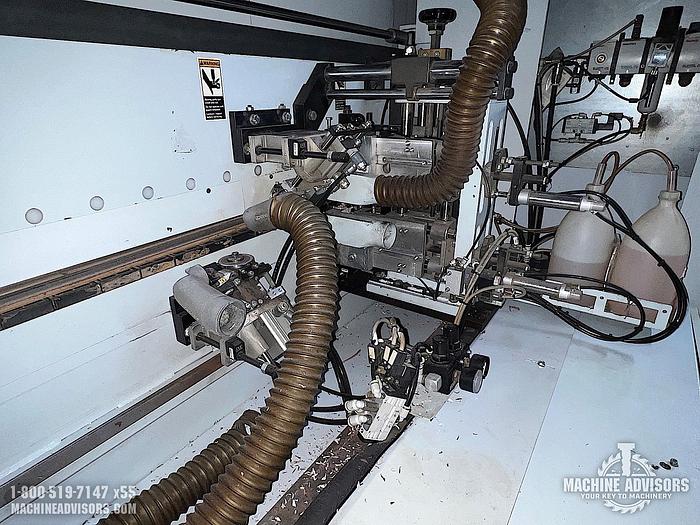

- Hot Melt Glue System: Quick Melt Unit with reversible glue roller applicator.

- Edge Magazine: Automatic 1-Coil/strip magazine, coils 0.3 - 3.0 mm.

- Pressure Section: Pressure roll section with (3) rollers. (1) Large dia. driven & (2) idle rollers; "NC" adjustment of pressure zone through the control for different edge thicknesses.

- Spraying Device: Top and Bottom spray nozzles for applying separating agent, for easier cleaning of any residual glue on panel.

Workstations:

- End Trimming Unit: (2) Motors, 0.5 kW (0.7 HP) - 12,000 RPM each motor; cuts excess edge on the front & back of the panel.

- Flush/Pre-Trimming Unit - Top & bottom Trim Station, 1.5 kW (2.0 HP - 12,000 RPM) Motor; +/- 1° angle adjustment, manual positioning with digital counters.

- Profile Trimming/Corner Rounding Unit: (2) Multifunction motors to process the edge overhangs at the workpiece upper & lower edge, as well as trimming around the front & rear edge; (2) 0.55 kW (HP 0.73) each motor.

- Open Station: Open space of 23.6" (600 mm), for future installation of a working unit.

- Profile Edge Scraping Unit: Electro-pneumatic adjustment.

- Finish Process Unit with Glue Scraper + Buffing Unit: Flat top & bottom panel surface glue scraper & buffing, removes any potential squeezed-out glue residue.

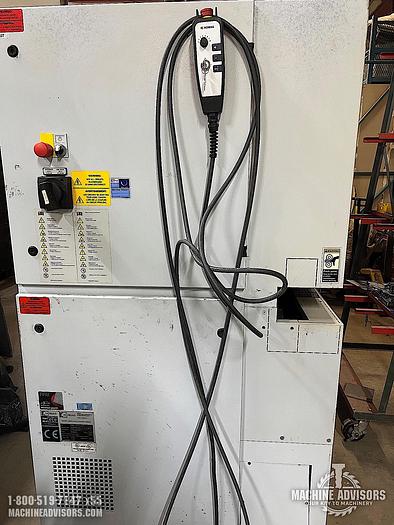

Operator & Machine Control:

- HOMAG "Power Control PC 22 + Windows "XP" operating System.

- Controller on separate console with 19" flat screen display, keyboard, and mouse.

- Includes fault diagnostic, OS9 real -time operating system.

- Complete with & Features Electronic DC brakes on all trim motors; sound cabin for all workstations. Adjustable outboard panel support with swing out arms for up to 800 mm. 80 mm Feed track pads; manually adjusted V-groove belt on top pressure beam, and Sound/Safety enclosure over workstations.

- Actual Model is HOMAG KAR 310/6/A3/S2 "RIGHT-HAND" Feed Configuration.

Specifications

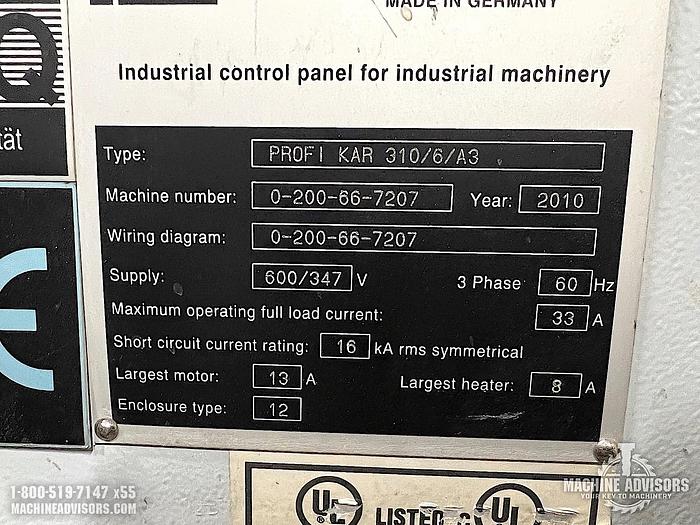

| Manufacturer | Homag |

| Model | Profi KAR 310/6/A3 |

| Year | 2010 |

| Condition | Used |

| Serial Number | 0-200-66-7207 |

| Power | 400V, 60Hz, 3Ph |

| Location | Brantford, Ontario |