2016 Homag Brandt Edgeteq S-380 1650FC

2016 Homag Brandt Edgeteq S-380 1650FC

Available quantity:1

Description

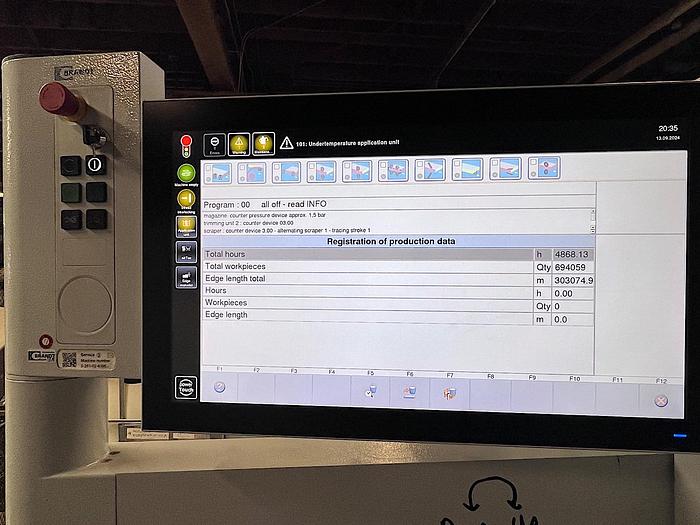

Homag / Brandt Edgeteq S-380 - 1650 FC Fully Loaded Edgebander

- powerTouch Program Control

- electrical equipment installed according to UL regulations

- motorized top pressure roller hold-down beam for workpiece thickness adjustment

- automatic feed track lubrication system

- program-controlled infeed fence positioning

- support rollers for narrow workpieces

- automatic magazine for coil feeding from outside the machine

- Separating Agent Spraying Unit

- Joint Trimming Unit for pre-trimming the workpiece edge prior to processing

- quick melt granulate glue application system

- quick change glue tank for easy maintenance and glue color change, if necessary

- PREPARATION: software, electrical pre-installation and mounting preparation for the later addition of the AT 20 airTec Reactivation Unit

- Lubrication Agent Spraying Unit for delicate materials like high gloss

- infrared radiant quartz heating unit between glue roller and pressure zone for optimum gluing strength

- program-controlled positioning of the pressure zone. First pressure roller driven and three (3) idle pressure rollers

- Double-Motor End Trimming Unit with straight and chamfer capability. Chamfer up to 15-degrees. Program-controlled indexing from straight to bevel end trimming

- Rough Trimming Unit with two (2) motors for top and bottom rough or flush trimming

- MS 45 Multi-Stage Fine Trimming Unit with three (3) working positions: Profile 1, Profile 2, and Flush Trimming. Auto-tilt and servo-controlled edge thickness. Nested top and bottom copy system (R = 1.3 / R = 3 mm)

- MF 60 Multi-Function Contour Trimming Unit for continuous trimming and profile corner trimming. Magnetic Linear Drive System with “soft touch” feature (R = 3 mm)

- Quick-Change Profile Scraping Unit for rigid PVC edges with program-controlled indexing (R = 1.3 / R = 3 mm), and nested top and bottom copy system (R = 1 mm)

- Grooving Unit with jump control (7 mm grooving tool)

- Finish Scraping Unit

- Detergent Agent Spraying Unit for cleaning the workpiece

- Buffing Unit with two (2) motors, two (2) cloth buffing discs (150 x 20 mm diameter)

- sound enclosure with centralized dust extraction outlet and LED lighting

- electronic frequency changer for all trimming motors

- isolation transformer with variable infeed voltage for balancing all three (3) phases of incoming power and increasing the lifetime of the machine’s electrical components

Specifications

| Manufacturer | Homag Brandt |

| Model | Edgeteq S-380 1650FC |

| Year | 2016 |

| Condition | Used |

| Stock Number | MA-0815230830-22 |

| Power | 230 Volt - 600 Volt |

| Location | Brantford, Ontario |